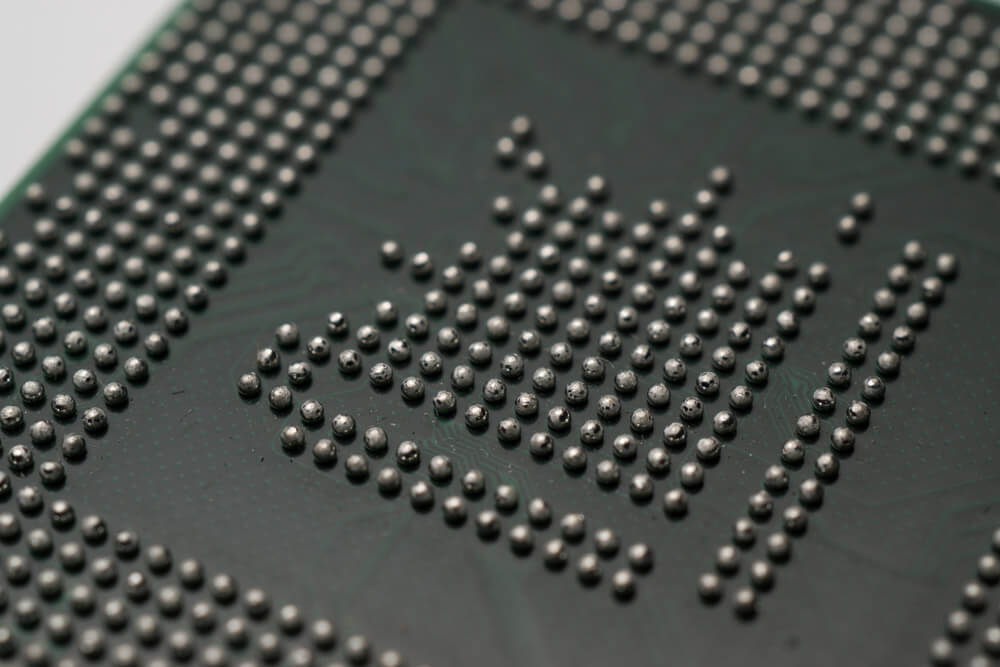

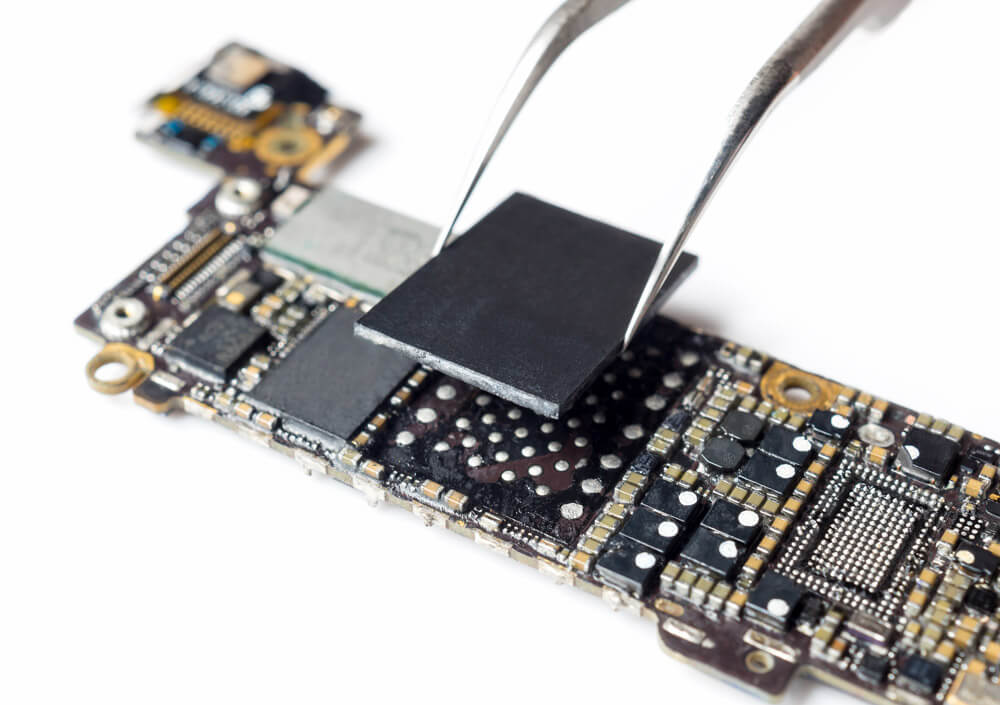

A laminate substrate is a type of material used as a base or platform for semiconductor packages. It serves as the structural foundation for connecting a semiconductor chip to the external circuitry. These package substrates are typically made of layers of reinforced resin materials (such as epoxy) combined with copper foils, forming a multilayer structure.

The core material is often a resin (e.g., epoxy) reinforced with materials like glass fiber for strength and thermal stability.

Copper layers are used to create electrical pathways and interconnections.

They are multilayered to accommodate complex interconnections and routing for high-performance chips.

Inner layers provide electrical pathways, while the outermost layers often include solder mask coatings to protect the circuitry.

Designed to handle thermal management needs and ensure proper electrical conductivity.

Dielectric layers provide insulation between conductive layers.

Laminate substrates are widely used in various semiconductor package types, including:

In summary, laminate substrates are crucial components in semiconductor packaging materials, providing a robust platform for chip attachment, electrical routing, and thermal management, enabling the integration of chips into electronic systems.