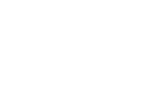

UTAC Group’s smart factories seamlessly integrate semiconductor manufacturing with cutting-edge Industry 4.0 technologies across our global operations, driving growth, enhancing workforce capabilities, and ensuring productivity and operational excellence.

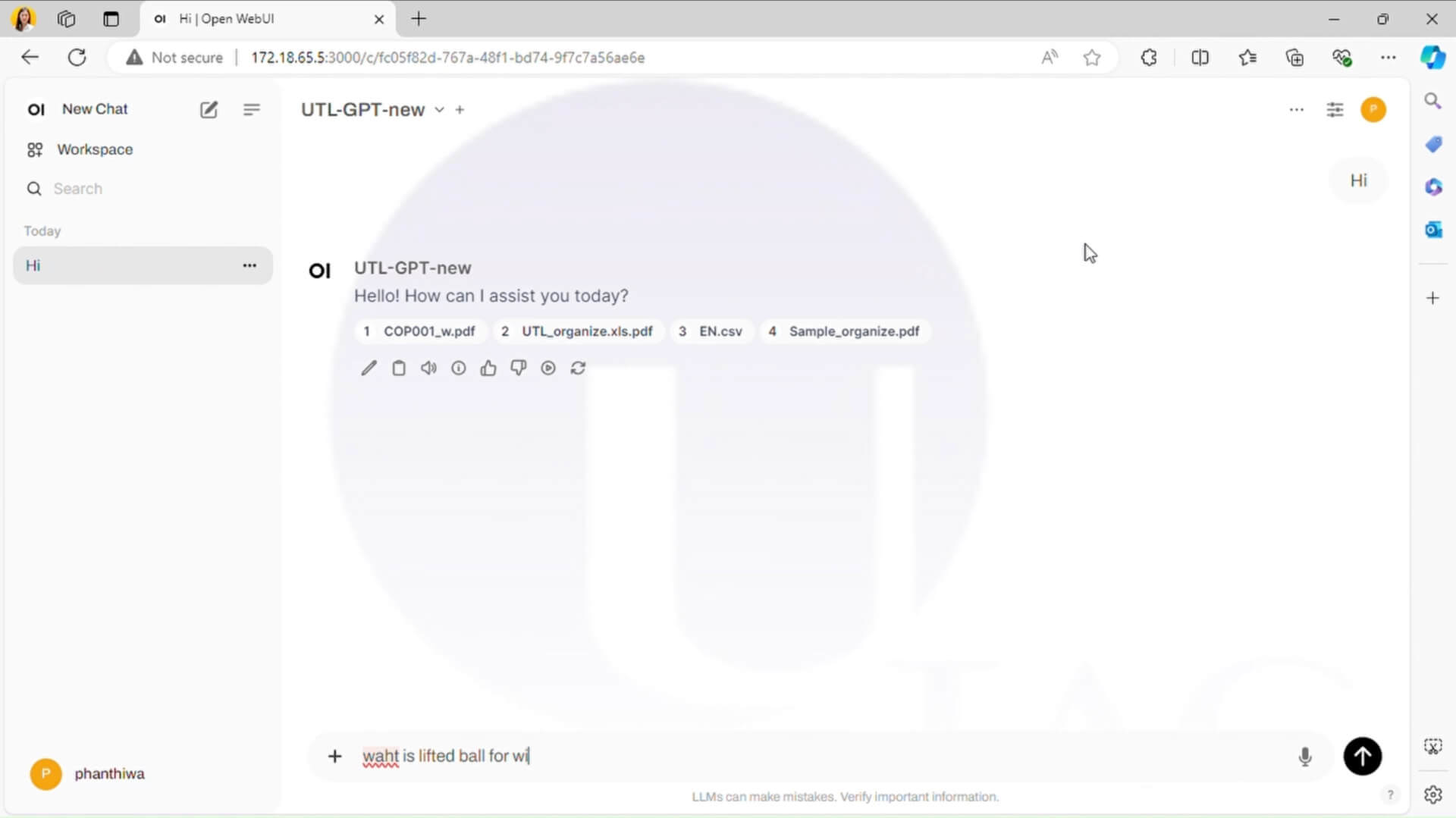

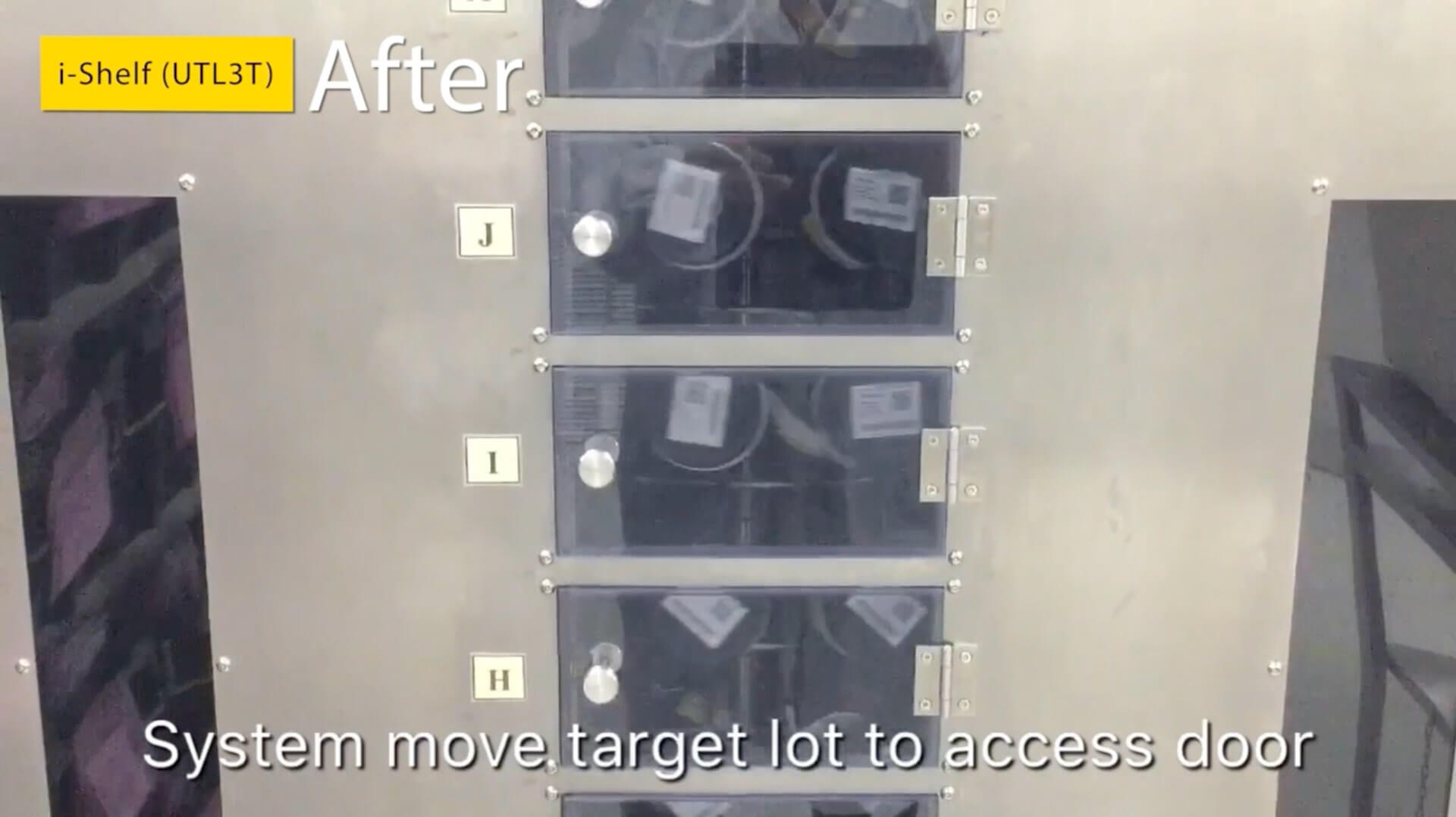

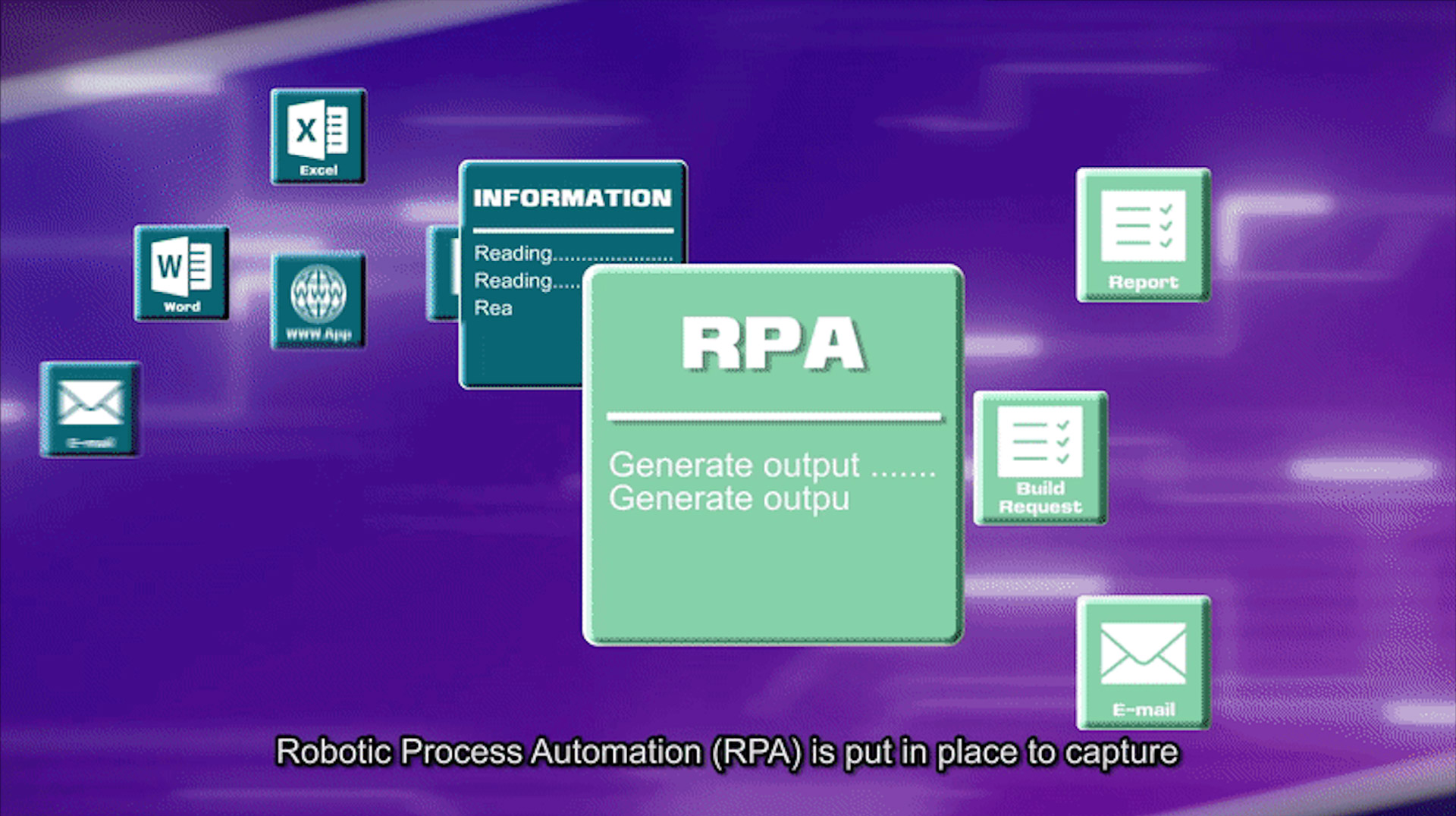

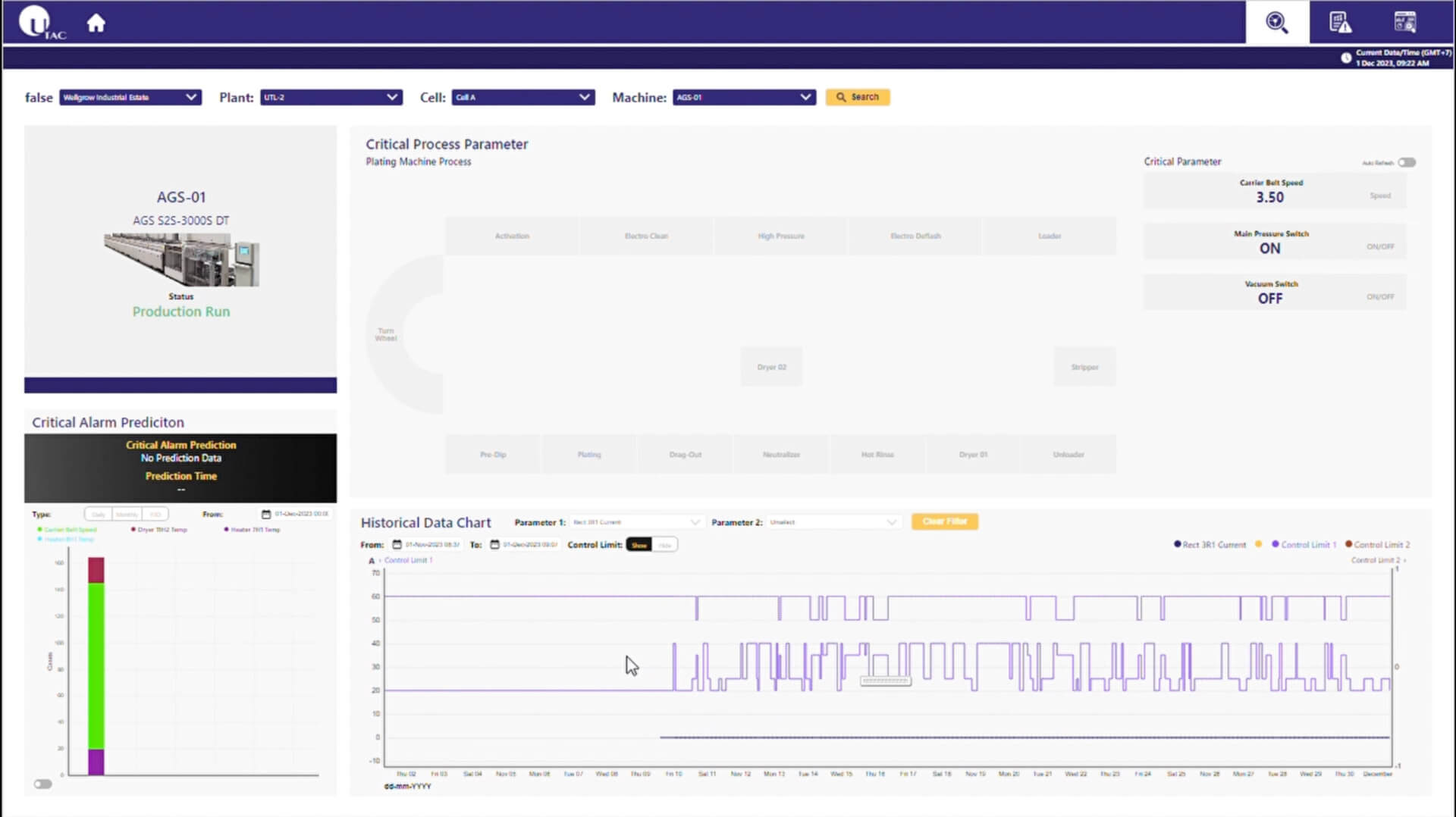

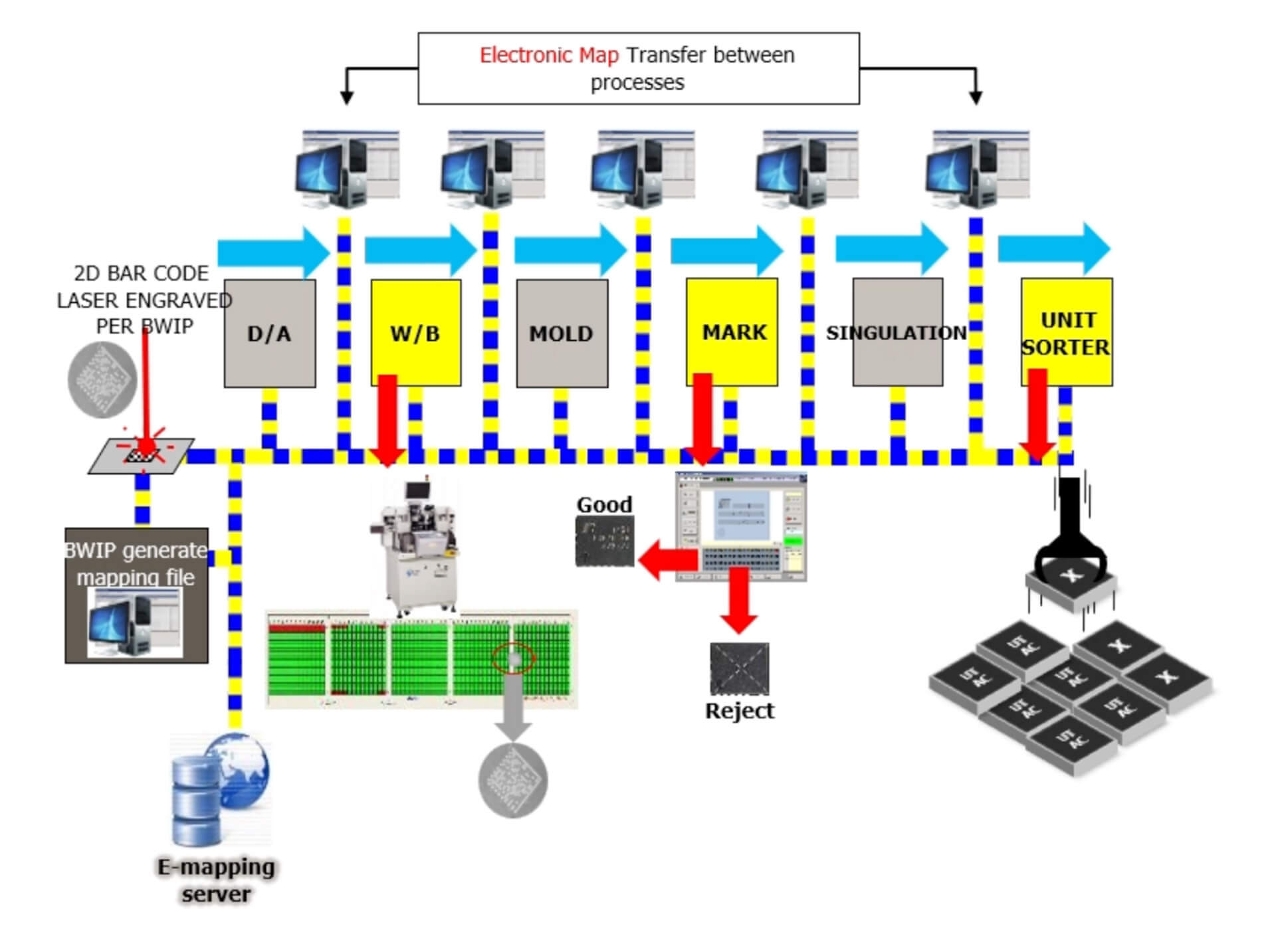

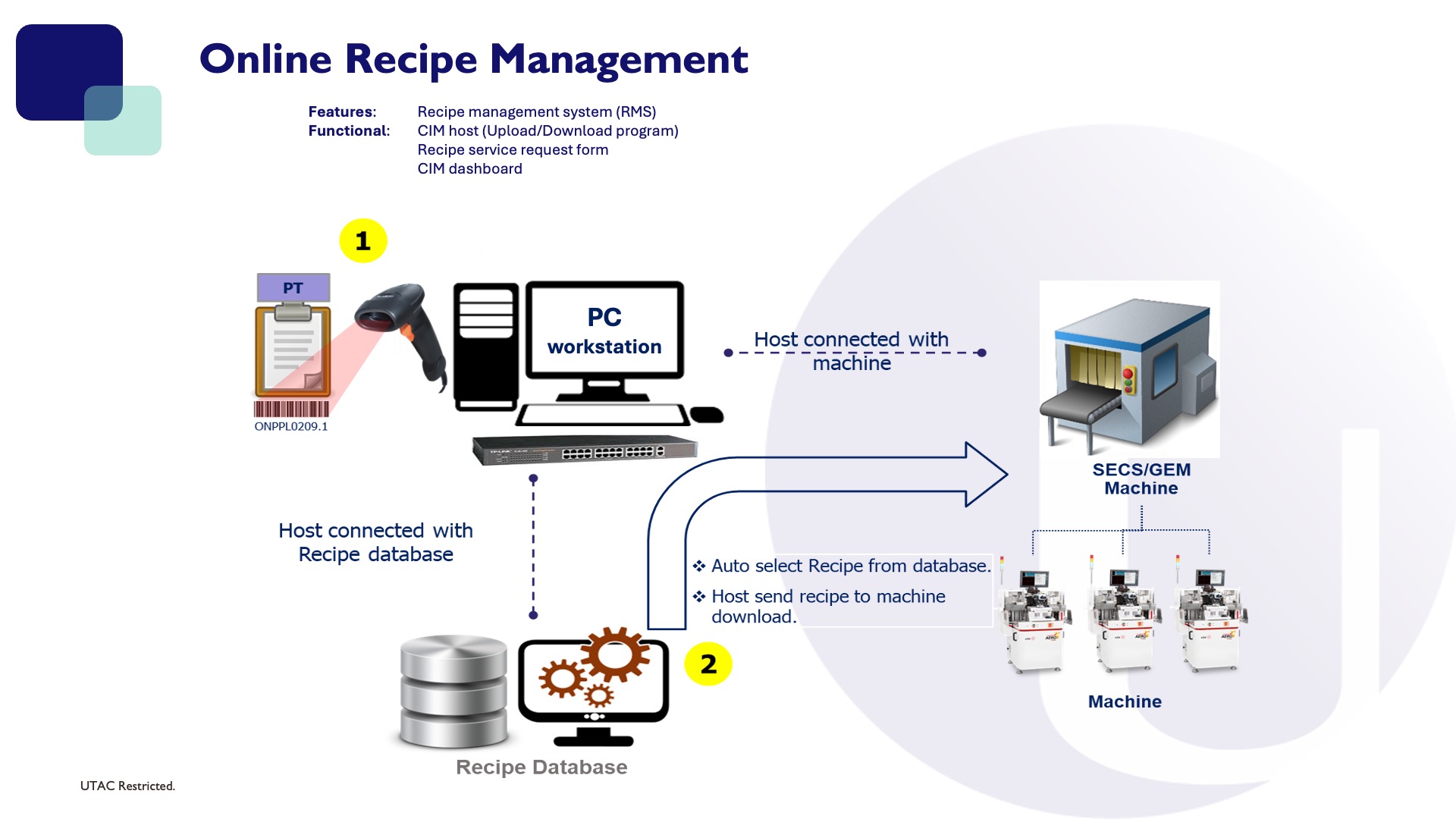

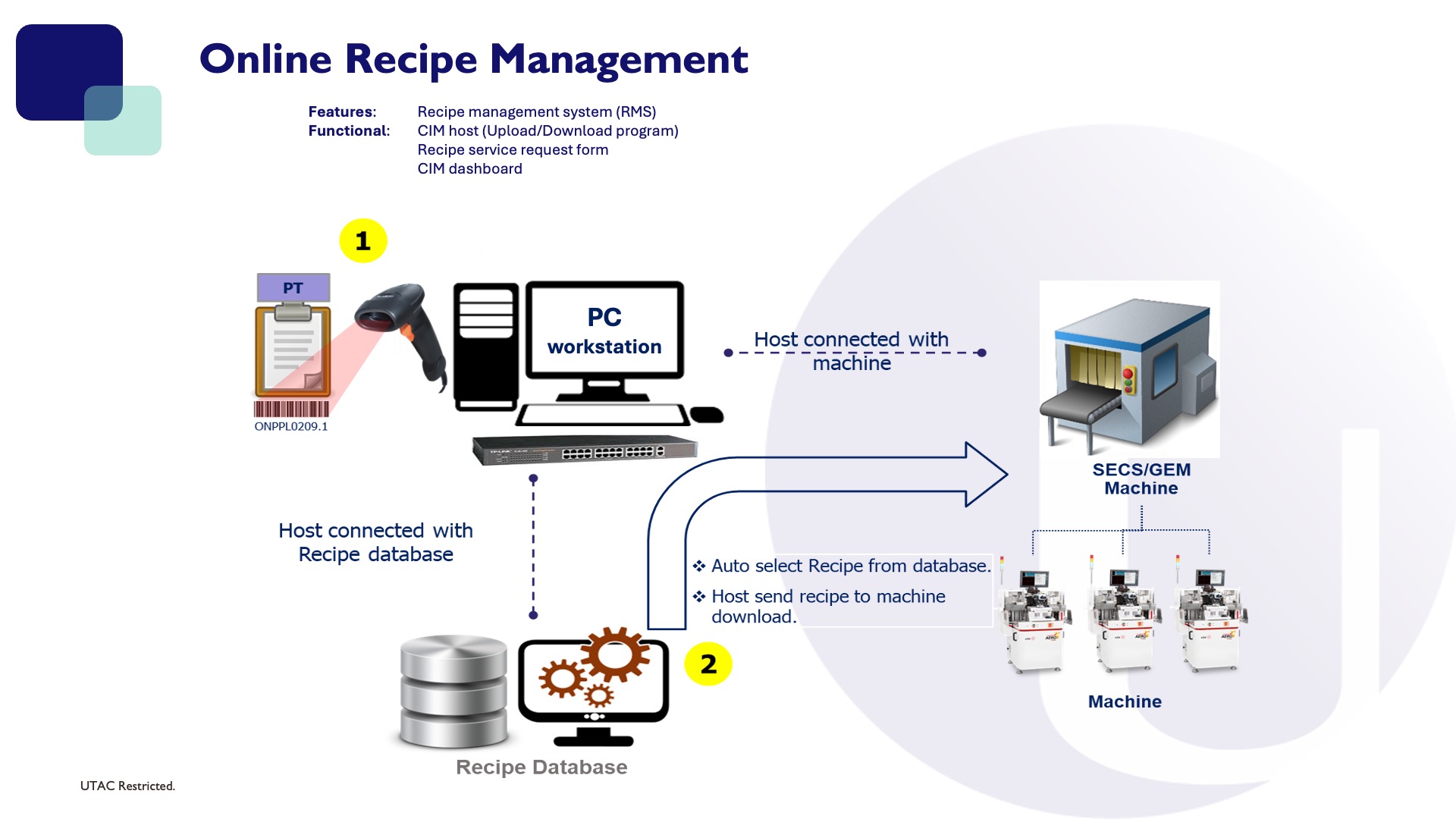

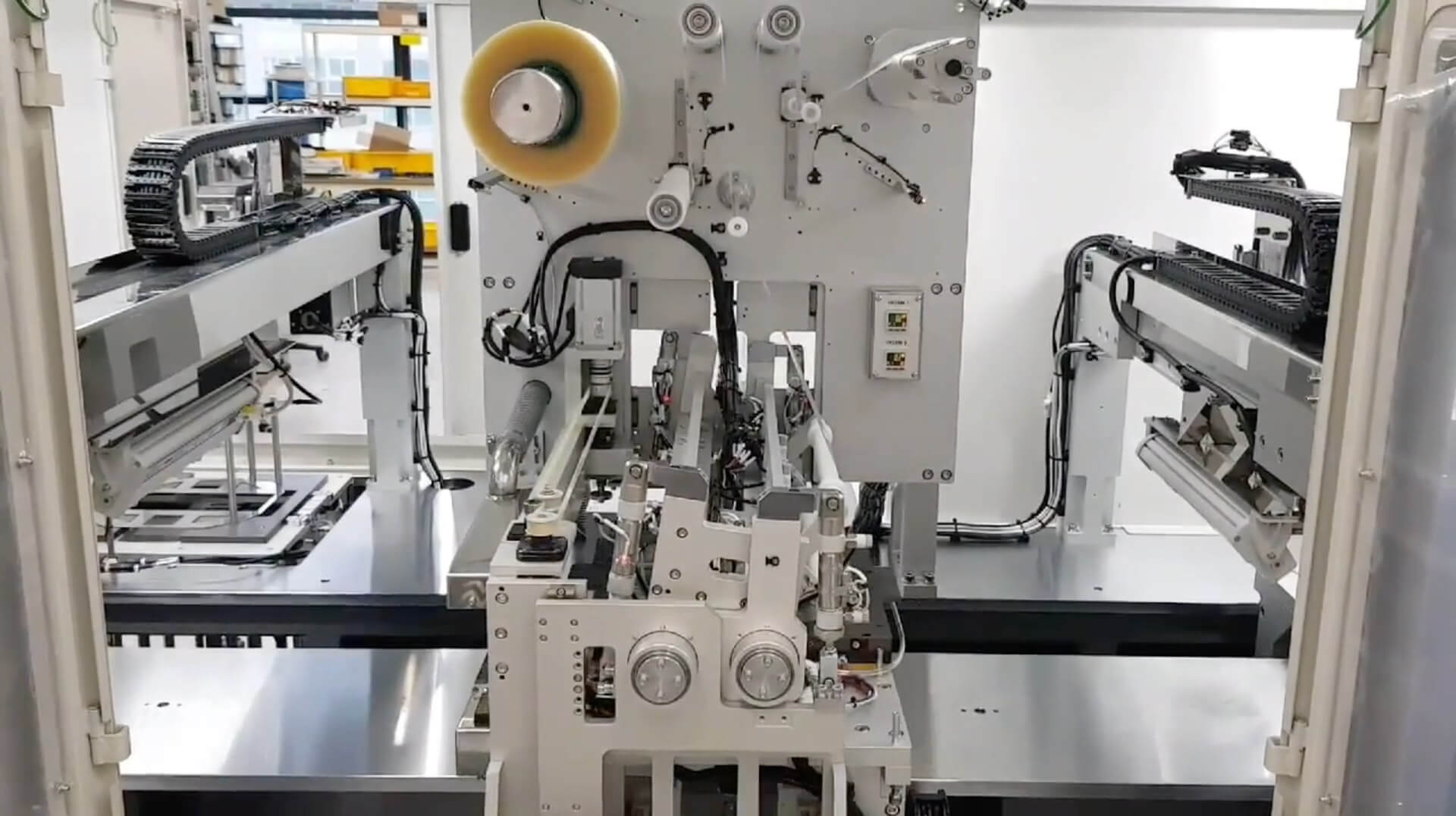

Our sustainable smart manufacturing solutions leverage advanced automation, IIOT platforms, machine learning, artificial intelligence, data analytics and remote monitoring capabilities. These technologies minimize quality issues, reduce manual processes, optimize data traceability, and elevate employee know-how.

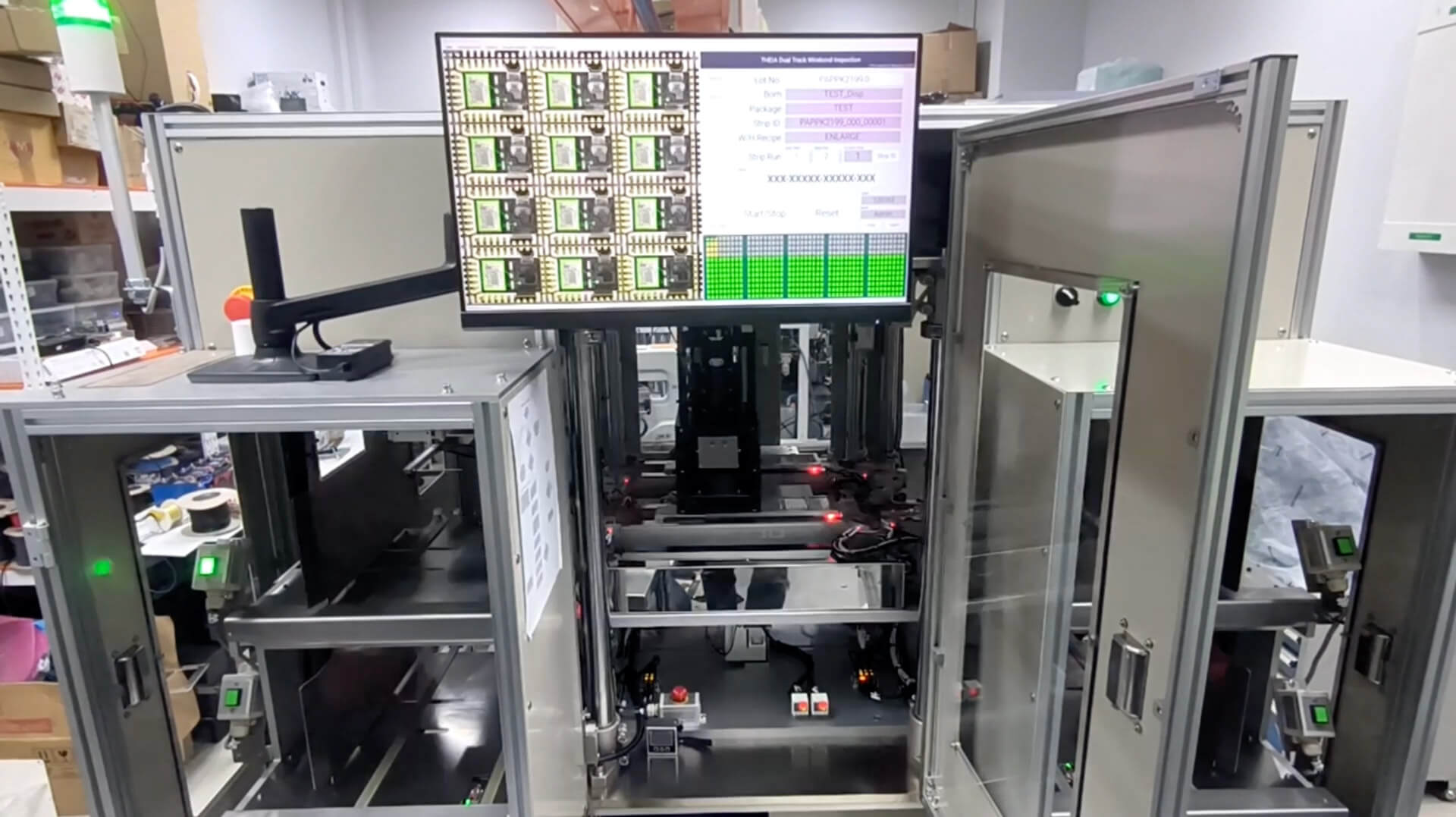

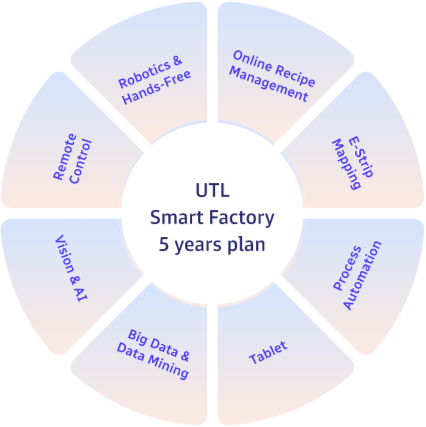

As an Industry 4.0 pioneer, UTAC facilities in Asia showcase cutting-edge smart factory technologies for semiconductor assembly and testing, including:

These state-of-the-art semiconductor production capabilities drive continuous improvements in operational efficiency, customer satisfaction, and international quality standards.

The strategic adoption of Industry 4.0 technologies places UTAC Smart Factories at the forefront of operational excellence in semiconductor manufacturing.