Imagine having a team of experts armed with cutting-edge simulation tools and a wealth of experience at your disposal. That’s exactly what you get with UTAC Group.

Our state-of-the-art facilities, measurement facilities and archive of 2,000+ in-depth analysis reports ensure we excel in thermal and mechanical analysis, electrical process analysis, FEA simulation, as well as comprehensive process analysis solutions.

We strive to lead the way in advanced packaging technologies, delivering exceptional value to our customers.

By fostering effective cross-functional team collaboration across all our sites, we ensure innovative solutions and unmatched service for our clients through robust product life cycle analysis.

Stay ahead of potential performance issues with failure prediction and optimization.

Get it right from the start. Design cost-saving strategies that accelerate time-to-market.

Understand the complexities with integrated chip (IC) assembly insights from our expert analysis.

Streamline for maximum efficiency with process resource optimization for critical applications.

UTAC provides complex IC assembly analysis across a wide range of packages including multi-chip modules (MCM), system-in-package (SiP), memory, Cu-clip, power applications, analog, mixed-signal, WLCSP, and wireless communication technologies.

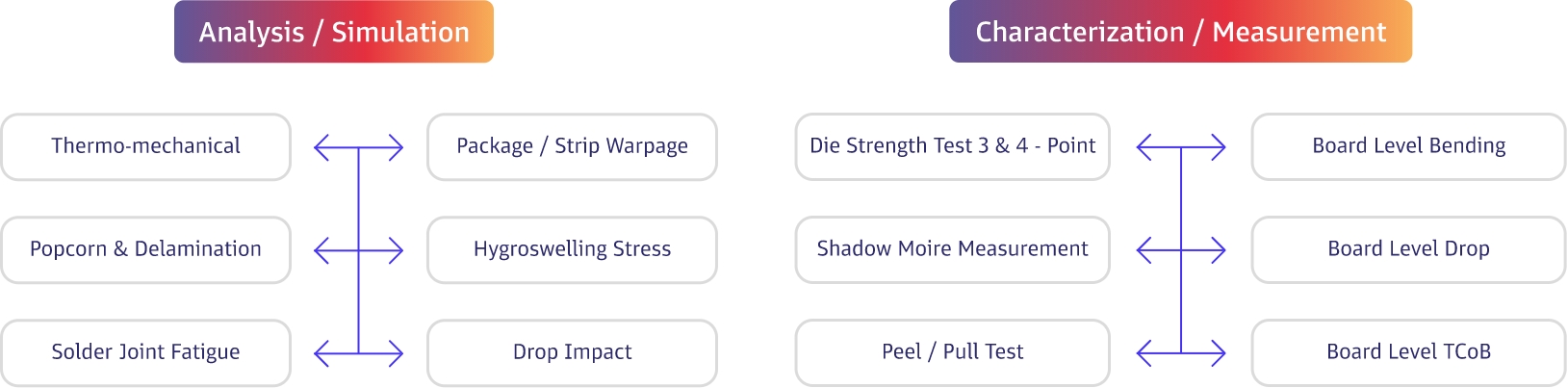

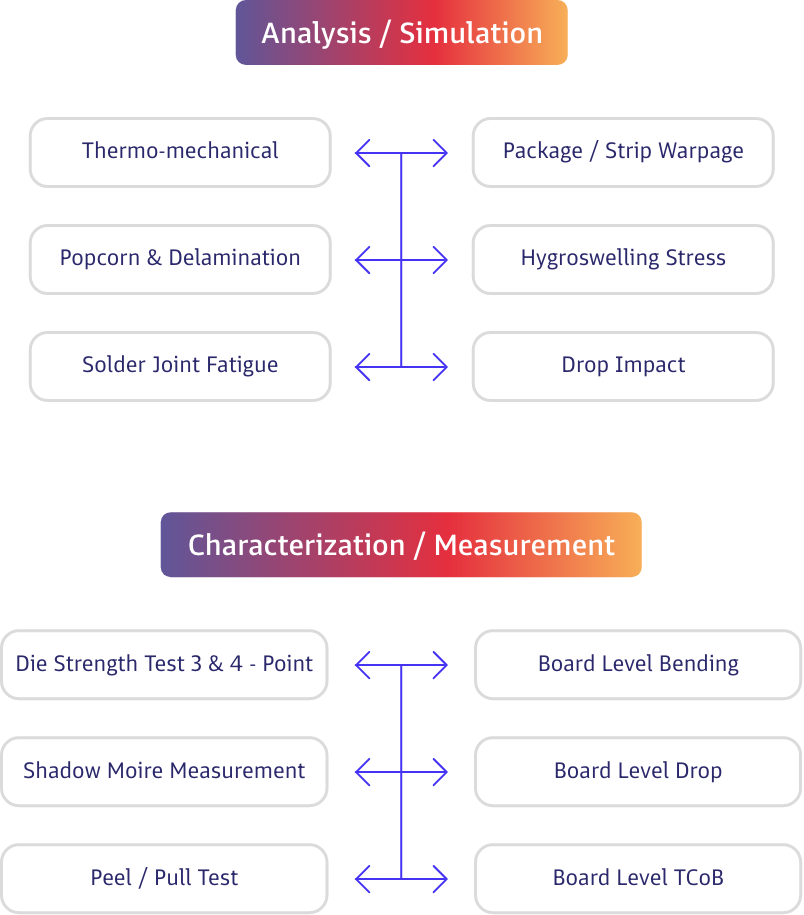

UTAC offers a comprehensive suite of advanced simulation capabilities and expertise, delivering tailored analysis services designed to meet even the most challenging thermal budgets.

Our dedicated team is committed to providing timely, high-quality solutions that improve thermal management and enhance product yield.

UTAC R&D has accumulated extensive knowledge and experience in both theoretical simulation and experimental characterization.

Our commitment to advanced packaging technologies and analyses is backed by a comprehensive technical library and analysis report expertise.

Whether it’s package or board-level analysis, we’ve got you covered with timely, high-quality solutions for your complex packaging needs.

UTAC Group provides a diverse range of packaging solutions, including WLCSP, power applications, analog, mixed-signal, and wireless communication packages.

Each package type has unique electrical characteristics that impact signal and power integrity.

To ensure optimal interconnect performance, device-specific electrical modeling and characterization are essential. UTAC Group’s expertise and advanced simulation capabilities are designed to meet the evolving demands of modern packaging solutions, including cutting-edge technologies. Our electrical analysis encompasses the entire process—from pre-layout design and optimization to package performance verification and reliability assessment.

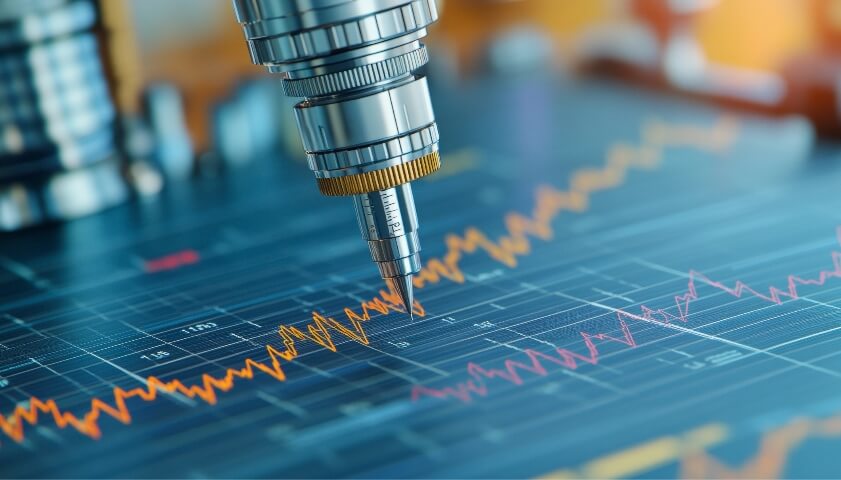

Electrical Simulation and Measurement Tools and Services

Our simulation capabilities include low and high-frequency analysis, power and signal integrity, impedance matching, and full-wave analysis, ensuring optimal performance based on complex IC assembly analysis.

UTAC Group has a comprehensive suite of advanced analysis tools to offer a wide variety of analysis services specially designed to meet our customers’ needs, with a particular focus on challenges relating to process loading reduction, cycle time reduction techniques, and enhanced product yield.

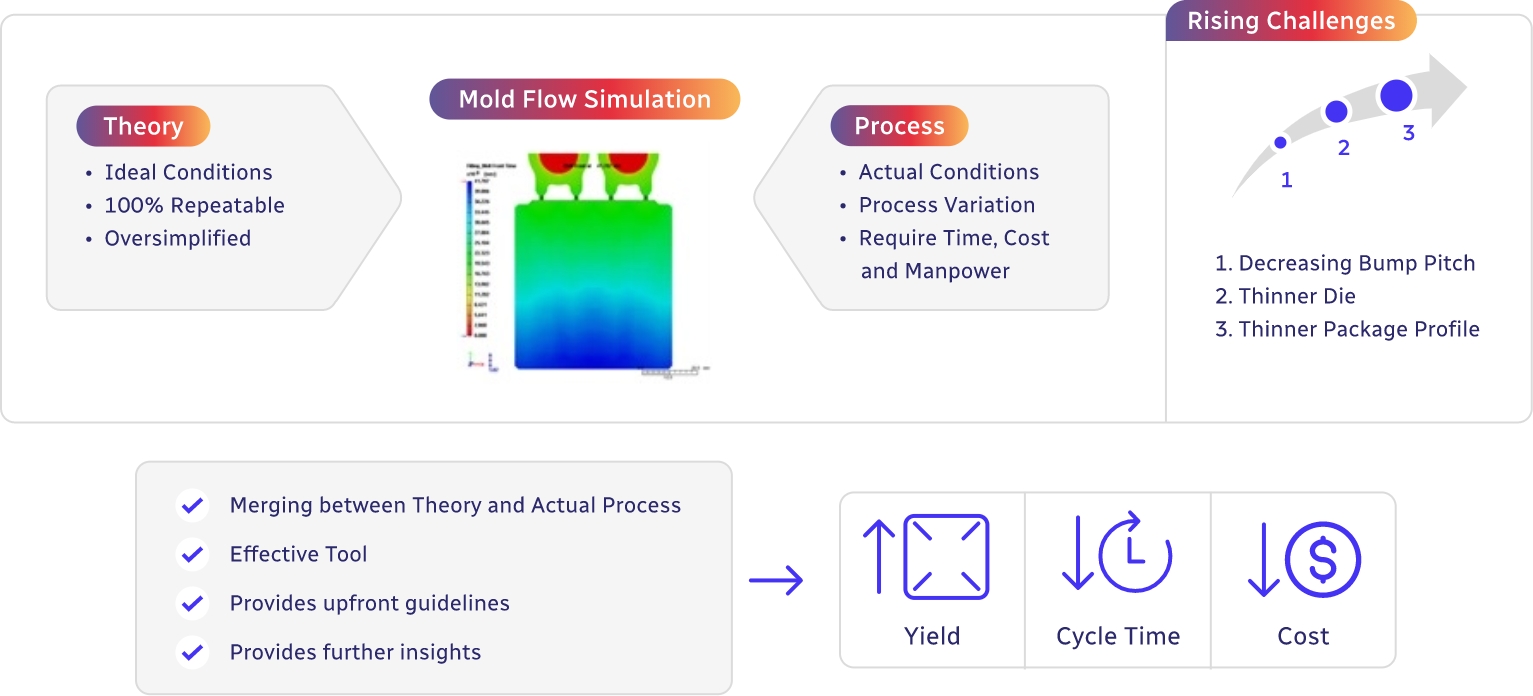

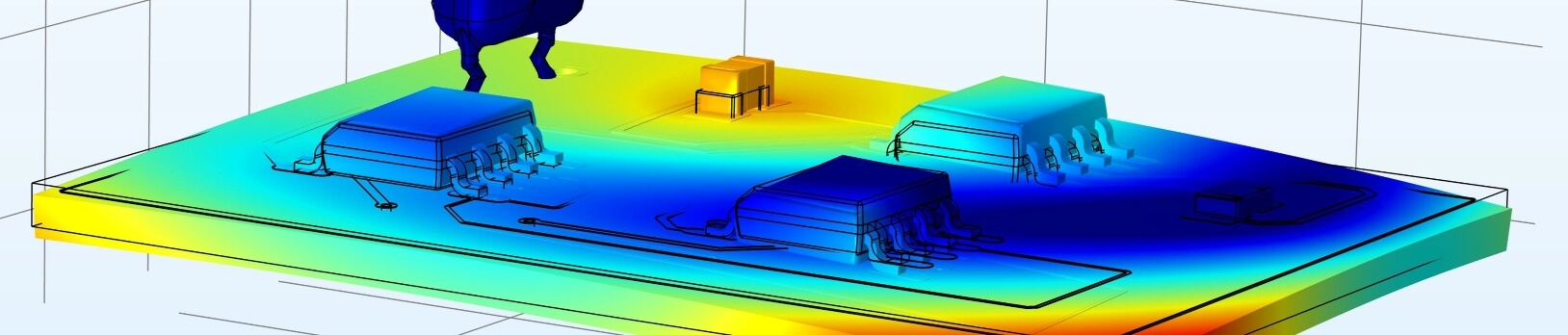

The rapid advancements in flip-chip technology, such as tighter bump pitches and reduced stand-off heights, present increasing challenges in ensuring moldability, particularly when utilizing commercial Moldable Underfill (MUF) during panel-level molding.

Traditionally, resolving this problem involves extensive experiments with a large Design of Experiments (DOE) matrix, demanding substantial time and resources.

To mitigate this, we design cost-saving strategies with UTAC 3D moldflow simulation – offering you a strategic approach for optimizing design, material selection, and molding processes for process loading reduction.

By utilizing moldflow simulation, UTAC effectively reduces defects and minimize the DOE matrix required for empirical testing.

This simulation technology not only shortens the design-to-implementation cycle but also facilitates the early identification of key issues during the design phase.