Our in-house lab offers advanced Physical and Electrical Failure Analysis (PFA/EFA) for qualified projects, helping you pinpoint root causes with speed and precision.

Our FA labs are integrated into every UTAC factory, ensuring quick access to both Physical Failure Analysis (PFA) and Electrical Failure Analysis (EFA). This allows for rapid failure analysis turnaround, speeding up your project timelines.

Our quality assurance (QA) engineers can seamlessly leverage resources across multiple UTAC sites, ensuring efficient and timely support for failure analysis testing.

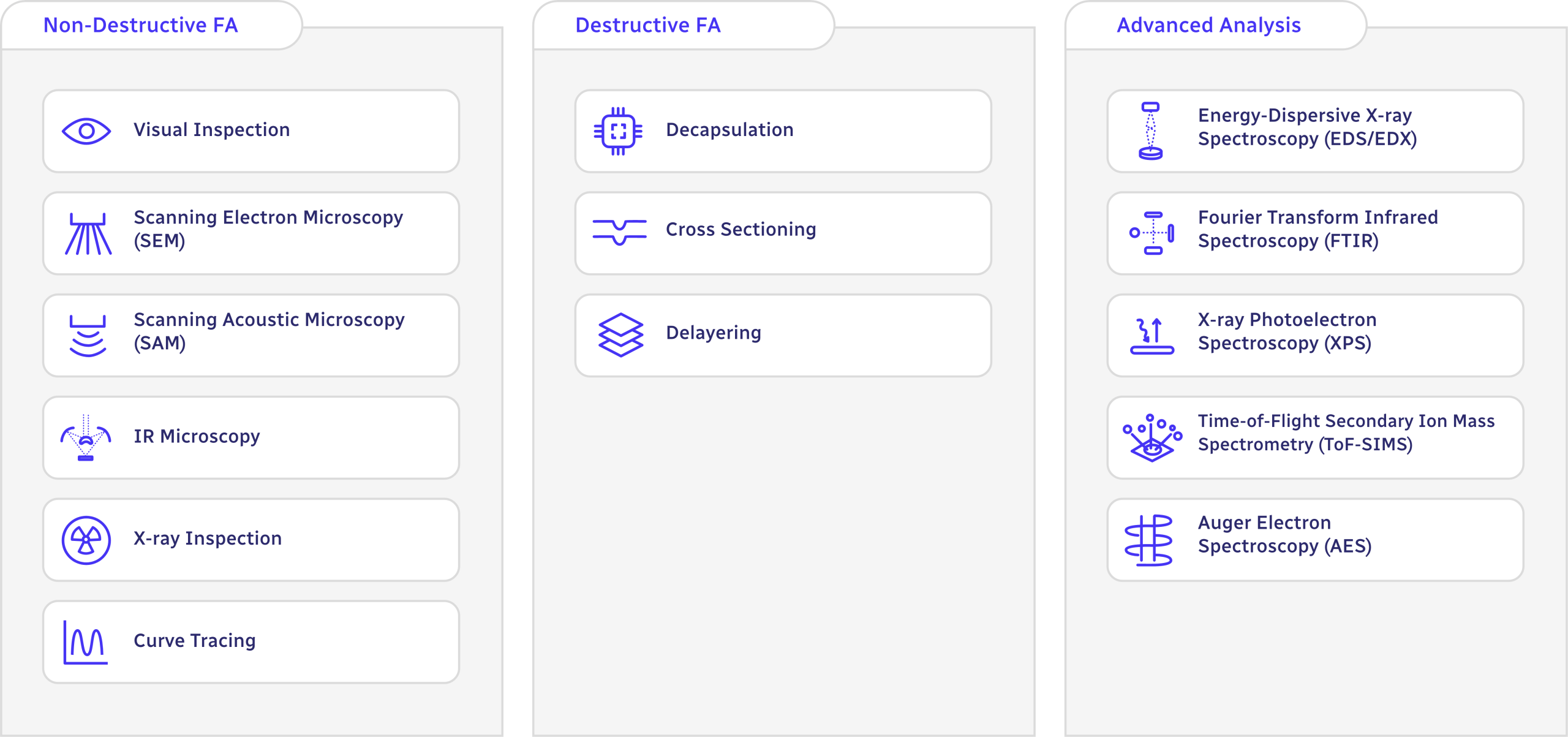

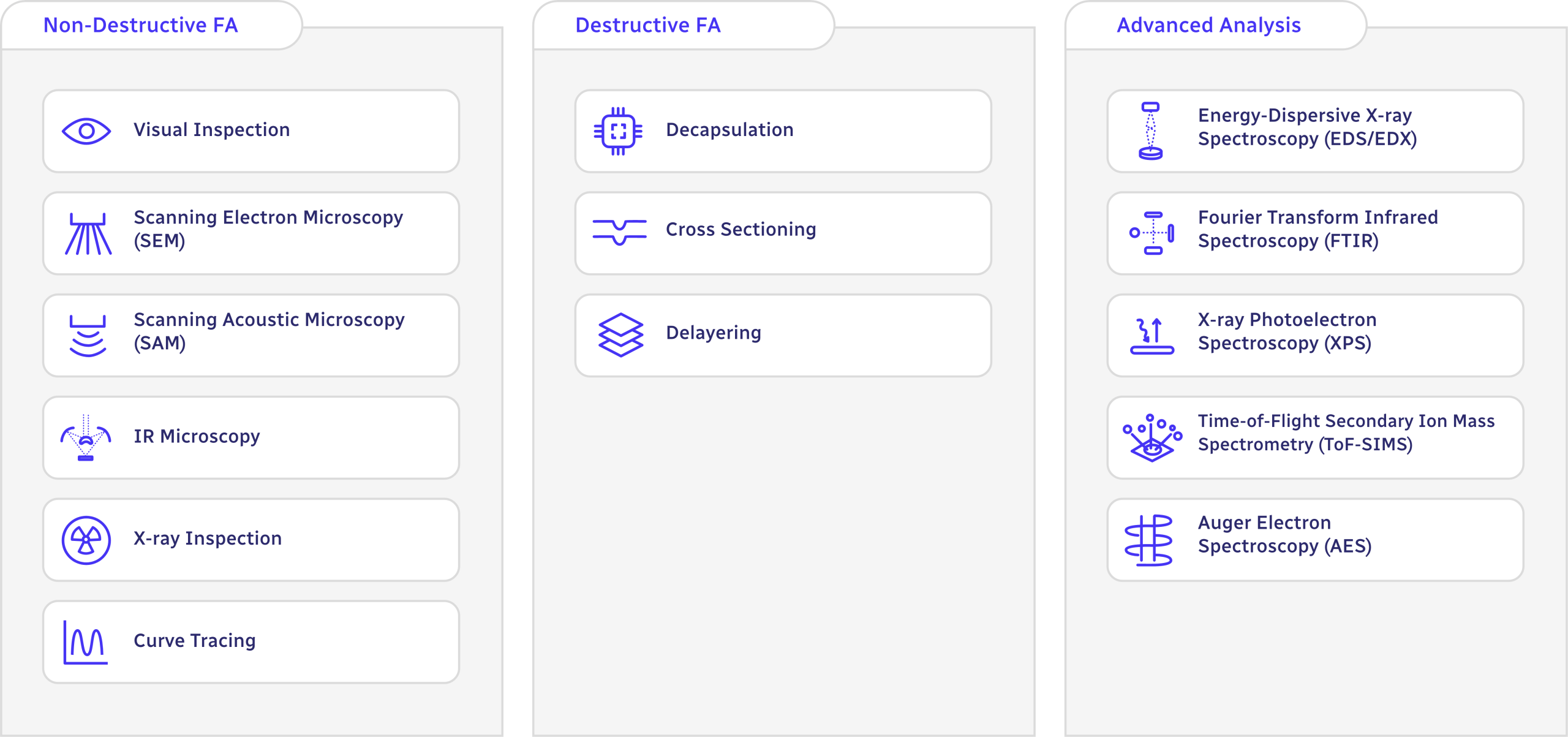

Our team of experienced engineers and technicians is equipped to handle a wide range of IC package failure analysis, PCB board failure analysis, and module testing needs. From Curve Trace analysis to advanced microscopy techniques, we’ve got you covered.

Through strategic partnerships with local analysis lab services, we offer advanced services like Focused Ion Beam (FIB), Transmission Electron Microscopy (TEM), X-ray Radiography and Scanning Acoustic Microscopy to thoroughly address every aspect of failure.

Our comprehensive failure analysis services offer solutions for IC and module failure testing, ensuring high-quality insights from both visual inspection services and advanced methods like Scanning Acoustic Microscopy and X-ray Radiography. Our capabilities are further enhanced with in-house FA capabilities, ensuring you have access to the most advanced tools and expertise needed to solve complex failure challenges.

Enquire Now

Each failure analysis test is expertly applied to uncover the root cause of failures, providing you with insights to enhance your semiconductor products.

Contact UTAC Group for Failure Analysis (FA) Lab Services today and benefit from our in-house FA capabilities, engineering and technician expertise, and local analysis lab services.