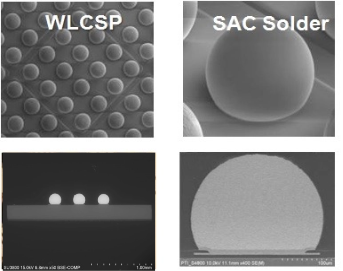

Wafer-Level Chip Scale Packaging (WLCSP) offers compact, cost-effective solutions that enhance performance and thermal efficiency. Combined with precision bumping technology, our WLCSP solutions ensure reliable electrical connections and meet the needs of high-density applications in mobile, automotive, and computing sectors.

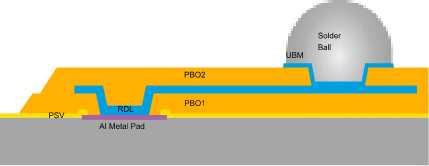

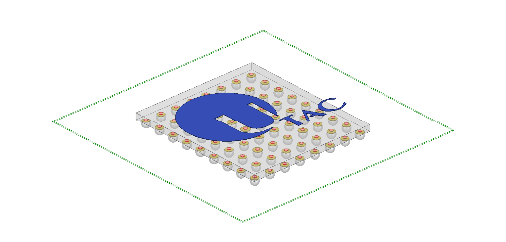

Package Structure:

0P1M / 1P1M / 2P2M

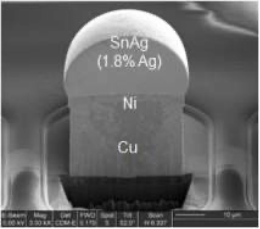

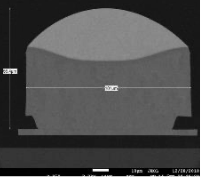

Bump Structure:

Cu/Ni/SnAg or Cu/SnAg with RDL option

Passivation:

Low temp / High temp PI & PBO including PFAS-free & low stress options

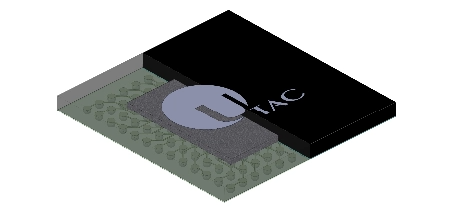

Package Structure:

1P1M / 2P2M

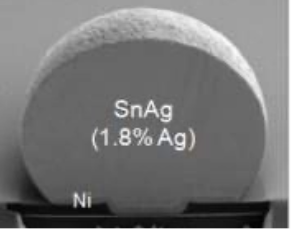

Bump Structure:

Ni/SnAg with RDL option

Passivation:

Low temp / High temp PI including PFAS-free & low stress options

Package Structure:

1P1M / 2P2M / 3P3M (dev) + Ball Mount

RDL & UBM:

Thick RDL & UBM options available

Solder Ball:

SAC405 / SACQ / LF35

Ball Pitch:

300 – 500um

Passivation:

Low temp / High temp PI & PBO including PFAS-free, low stress and thick PBO options

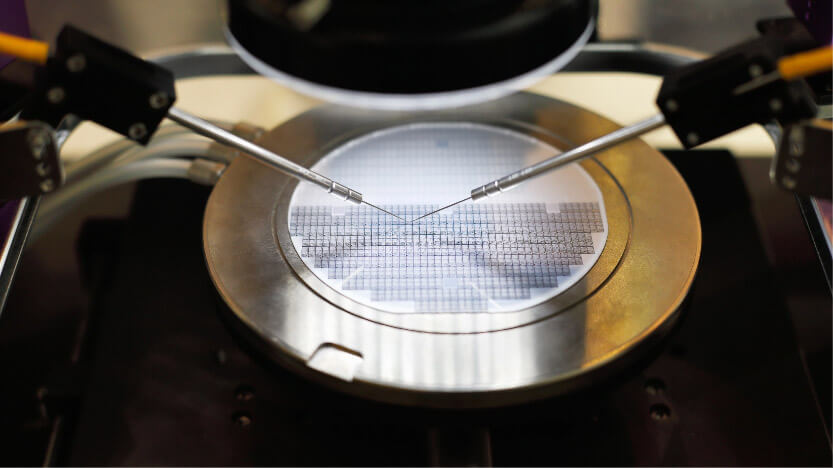

High Parallelism

Up to 32 sites for WLCSP and 1280 for Pad wafers

Temperature Range

-55˚C to +150˚C

Frame Probing

Singulated and Fan-Out Wafer

Blackbox Testing

Security Key Encryption on Wafer Level

Wafer Size

8″ and 12″

Software Customization

Support GDBN and PAT* to drive toward zero defect”

Strategic Partnership

Long term partnership with foundries and probe card suppliers.

Multiple Probe card Technologies

Certified In house Probe card maintenance team.

Multiple Probe card Technologies