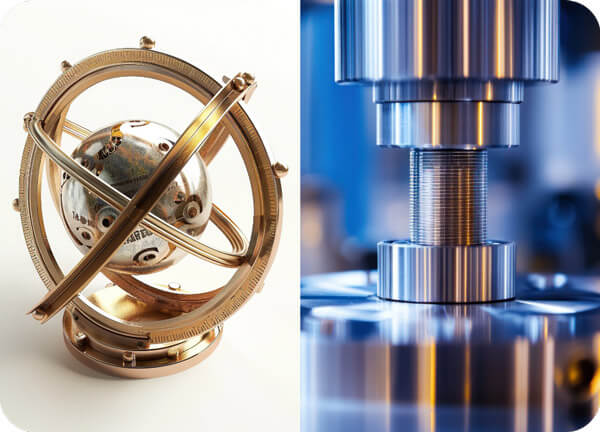

MEMS and Sensors have become ubiquitous, embedded in everything from motion sensors in smartphones, altimeters in smartwatches, magnetic position sensors for industrial motors and engine management sensors for internal combustion engines, to current sensors for electrical vehicle drivetrains, and MEMS timing for high performance computing and wireless communications.

At UTAC, we provide semiconductor packaging solutions that ensure these MEMS/Sensor devices perform reliably over their lifetime while maintaining small form factor and without introducing any drift.

MEMS & Sensor devices’ performance is highly dependent on both the operating principle as well as the packaging used to house the dies. Our advanced packaging capabilities for MEMS & Sensor guarantee device performance whilst being scalable at high volume with fast time to market – all without compromising on durability and reliability.

For this reason, it is often the case that custom packaging and testing solutions are required for different MEMS & Sensor devices.

UTAC Group R&D teams collaborate closely with customers to develop the correct package design and select materials that strike the perfect balance between performance, reliability, size and cost.

With more than a decade of experience, we have broadened our MEMS & Sensor portfolio significantly to include diverse package structures and Bill of Materials, ensuring our solutions cater for numerous MEMS & sensing applications.

Today, we have many different device types running in high volume production, as well as many new products in development, in an assortment of package types, body sizes, multi-die layouts, and material types.

Beyond packaging, we also apply our vast test experience to MEMS & Sensor testing.

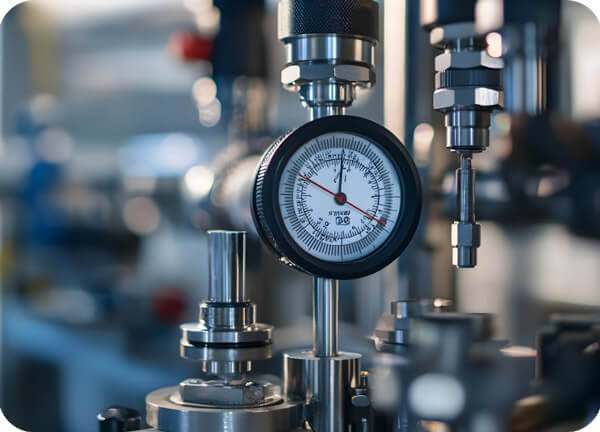

Our capabilities support both wafer probing and MEMS & Sensor final part testing, specifically addressing the key challenges of stimuli application and sensor calibration.

With a variety of testers from leading ATEs, and test handlers with different manipulation methods, we provide comprehensive turnkey packaging and testing solutions for our customers across a wide range of MEMS & sensor applications, including magnetic, current, pressure, fluidic, gas, and optical sensors amongst others.

Customizable designs to meet application-specific requirements.

Reliable packaging that maintains sensor performance over time without drift.

High-volume production capabilities with fast time-to-market.

From design and material selection, to assembly, testing and calibration.

UTAC is a trusted partner for companies seeking to elevate their MEMS and sensor devices with robust packaging and testing services.

Whether you’re innovating in automotive, consumer electronics, or industrial systems, our MEMS & Sensor expertise will ensure your devices’ performance over their lifetime.