UTAC Group, a leader in semiconductor assembly and testing, offers cutting-edge leadframe packaging solutions tailored to meet diverse industry needs.

With a strong focus on electrical & thermal performance, efficiency, and innovation, UTAC Group provides a comprehensive range of lead frame packaging technologies that cater to high-performance applications in industrial, telecommunications infrastructure, consumer electronics, and automotive markets.

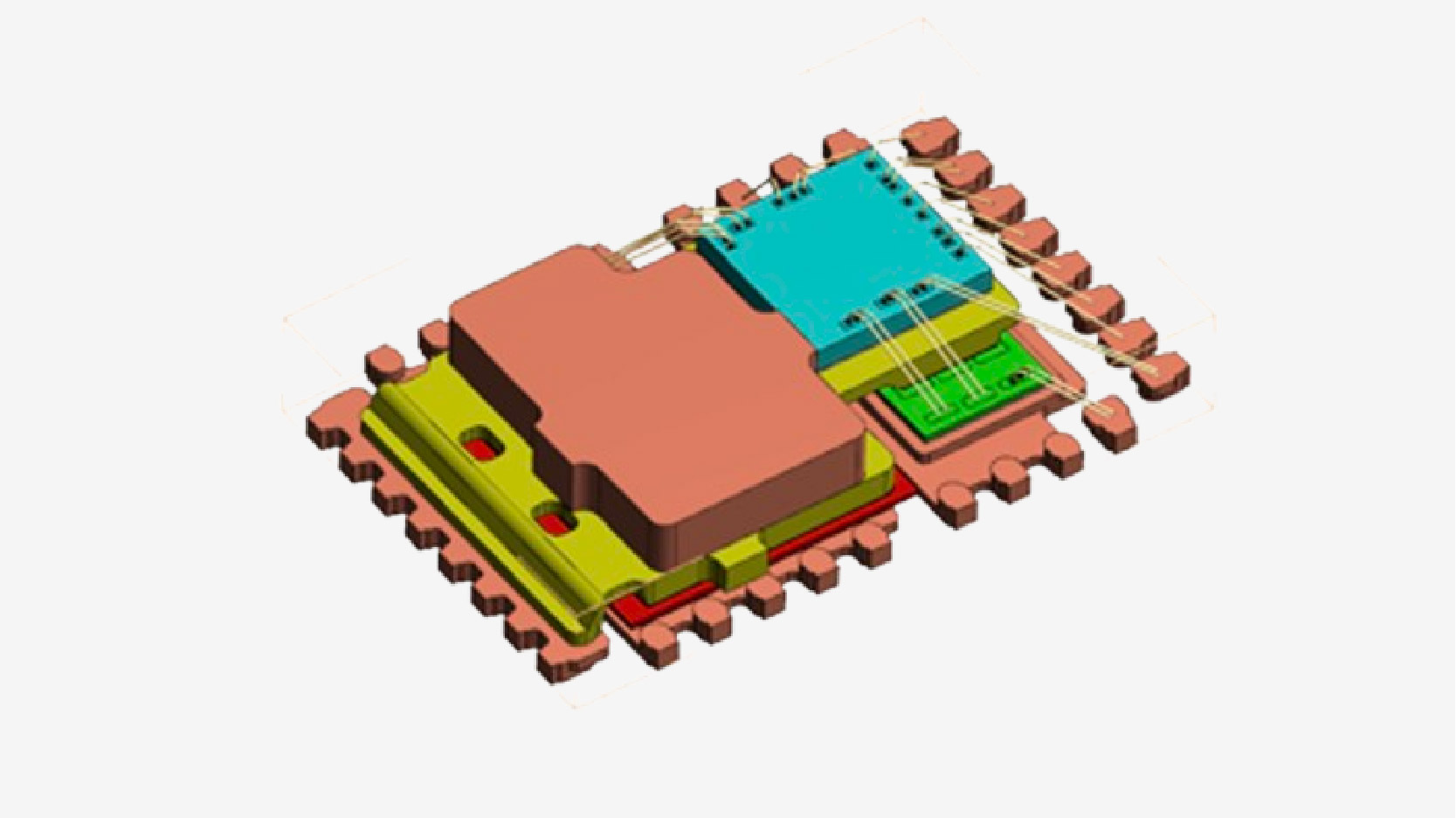

Copper Clip technology is a preferred alternative to traditional wire bonding for high-performance MOSFETs. As a market leader in MOSFET packaging, UTAC Group produces a wide array of QFN Cu Clip packaging to support leading IDMs and fabless companies.

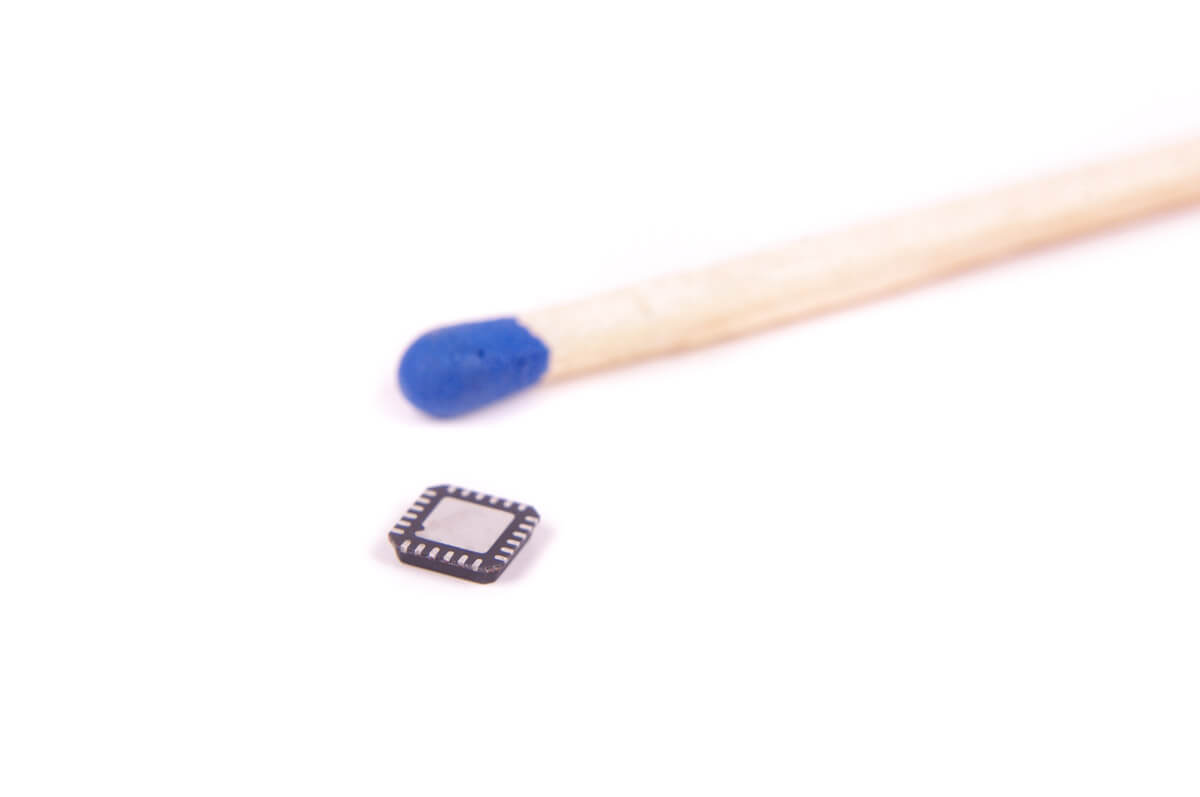

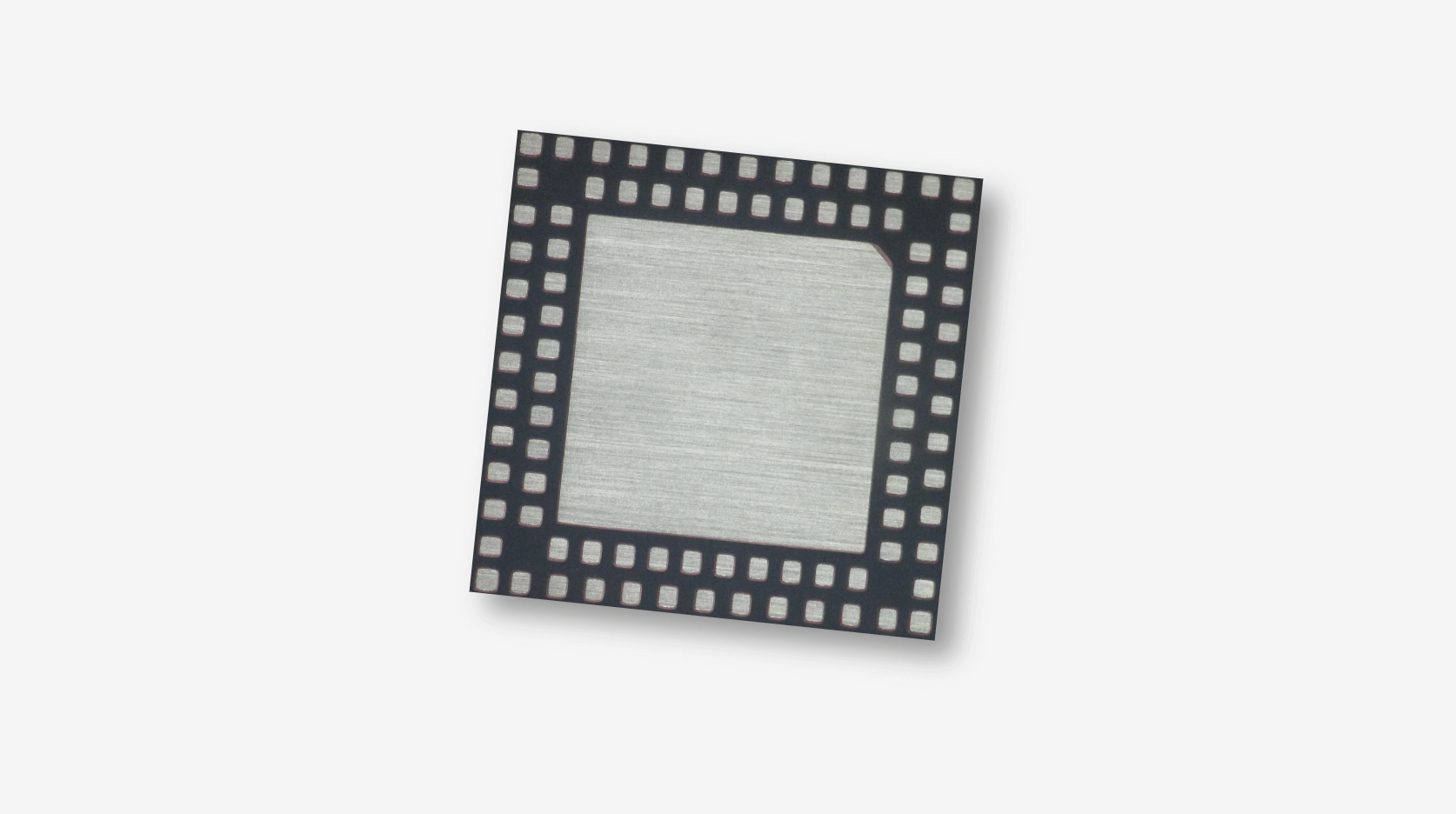

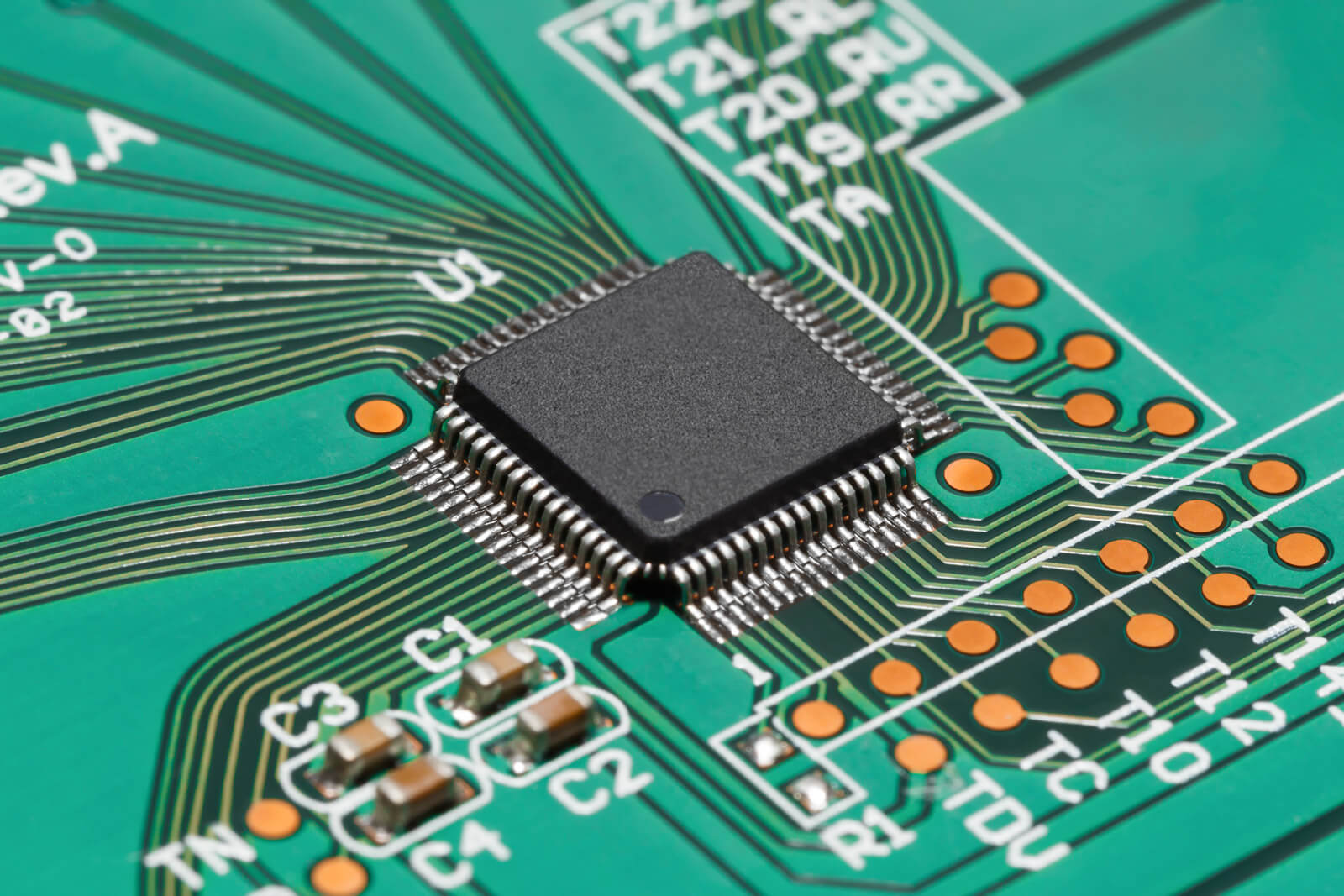

The Quad Flat No-Lead (QFN) package, introduced by UTAC Group in 1998, is a popular lead-less package.

TLA is a multi-row lead frame package, which uses advanced leadframes and assembly processes to offer a higher I/O density solution with exceptional thermal performance and smaller footprint than conventional leadframe packages.

UTAC’s QFP offerings include QFP, LQFP (Low-Profile Quad Flat Package) and TQFP (Thin Quad Flat Package) in various sizes and lead counts per JEDEC standards.

These packages are suited for applications requiring higher I/O count devices requiring high thermal, electrical and reliability performance.

UTAC offers a wide range of leadframe-based packaging solutions tailored for specific requirements:

Cost-effective industry standard package in both narrow and wide body formats, and exposed pad option.

Denser leaded packages with narrower lead pitches, including ultra-thin and exposed pad package options.

Ideal for low pin count, small form-factor designs, including SOT23, TSOT23, and SC70.

UTAC Group’s commitment to innovation, quality, and performance ensures that every leadframe packaging solution meets the highest standards of reliability and efficiency in semiconductor assembly services.

With decades of experience and a proven track record in supporting leading IDMs and fabless companies, UTAC Group is the partner of choice for cutting-edge semiconductor packaging needs and turnkey assembly and test solutions.

Explore how UTAC Group’s leadframe packaging solutions can elevate your product performance and drive innovation in your industry.