In recent years, image sensor adoption has surged due to advancements in technology and diverse applications across several industries.

Key drivers include the proliferation of high-resolution sensors in smartphones, the rise of ADAS and autonomous vehicles in automotive, and increasing use in healthcare, industrial automation, and security systems.

Emerging technologies like AR/VR, drones, and IoT further highlight the growing importance of image sensor solutions.

UTAC Group has over two decades of experience in advanced image sensor packaging and testing, supported by advanced technology roadmap developments and manufacturing operational excellence, making UTAC Group a market leader for image sensor packages.

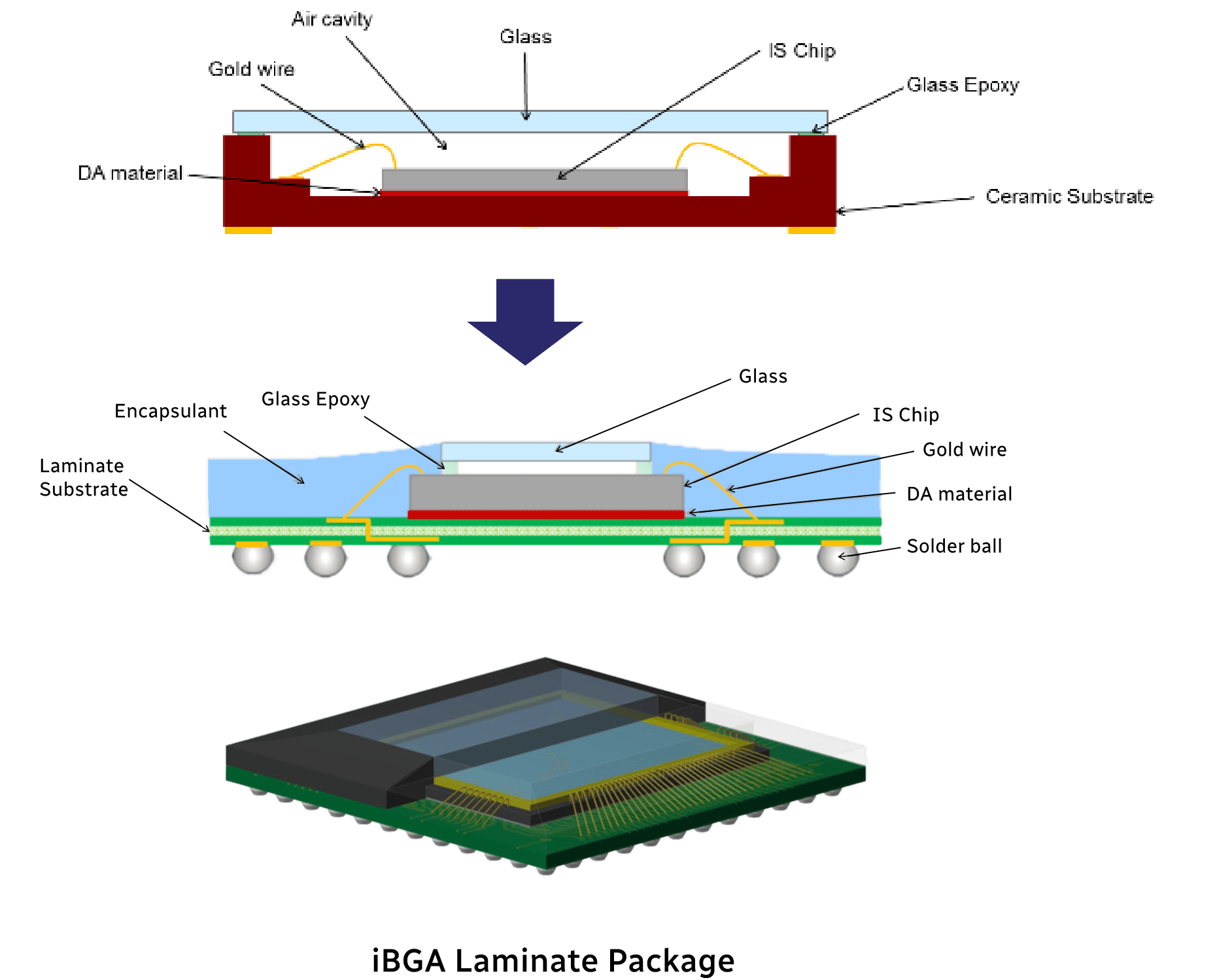

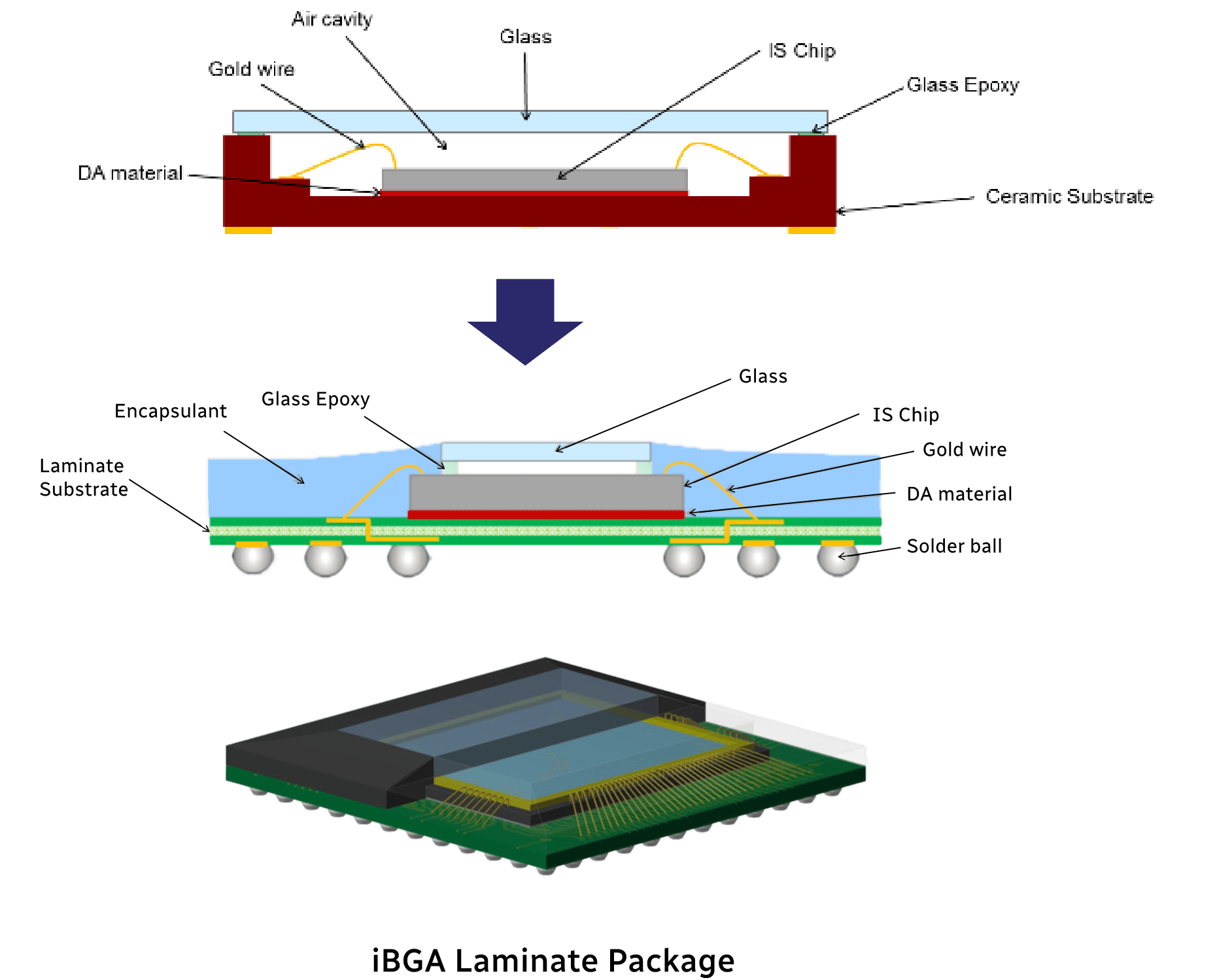

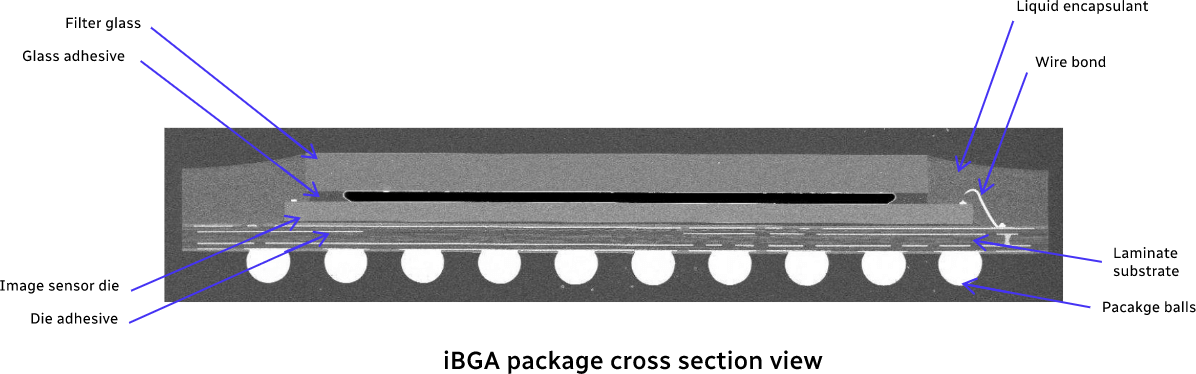

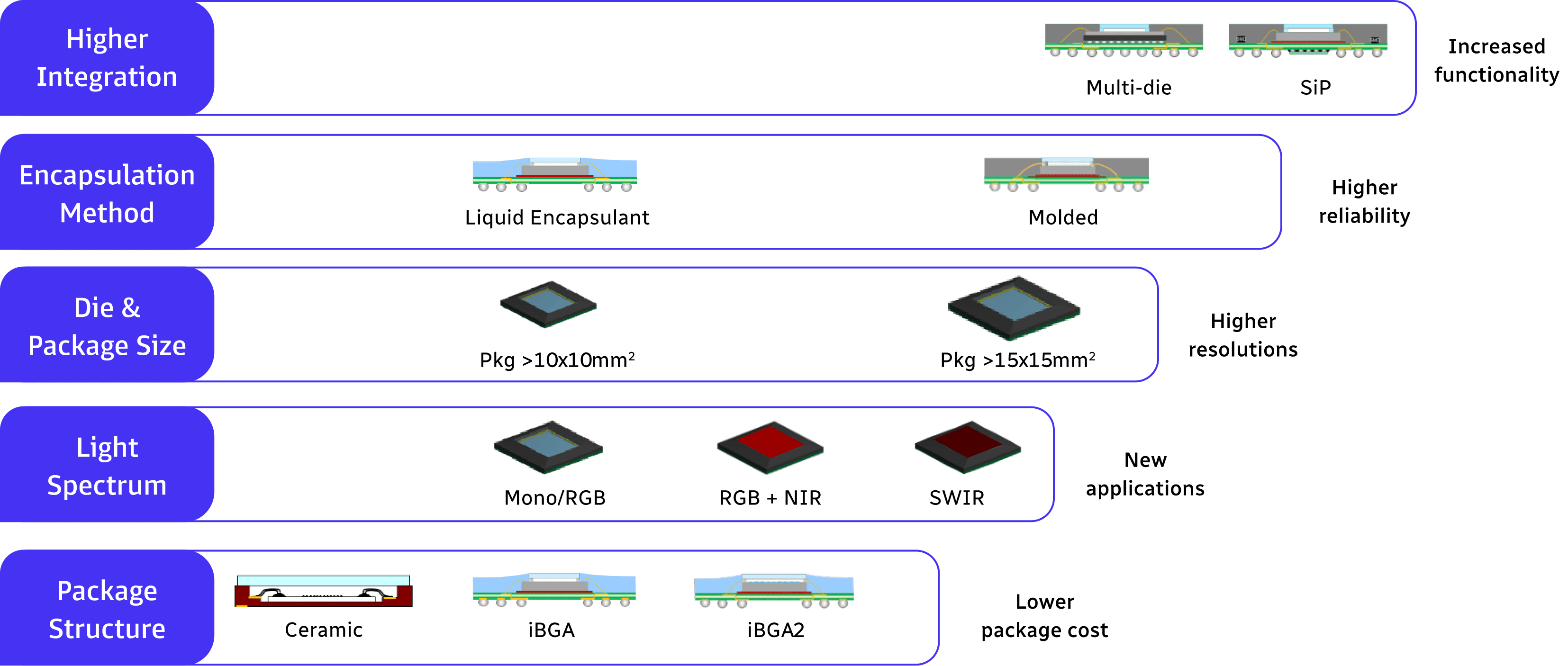

UTAC Group manufactures CMOS image sensor devices in both ceramic and laminate packages for several leading imaging customers. The development of our iBGA technology (imaging BGA) allows us to offer robust laminate package alternatives to ceramic packages, with higher I/O density, lower cost and faster development times whilst still meeting stringent automotive grade reliability.

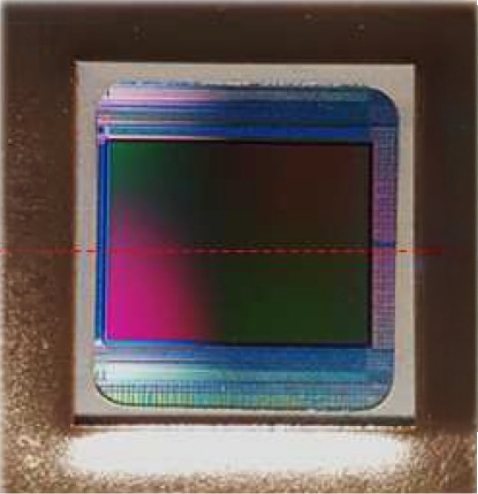

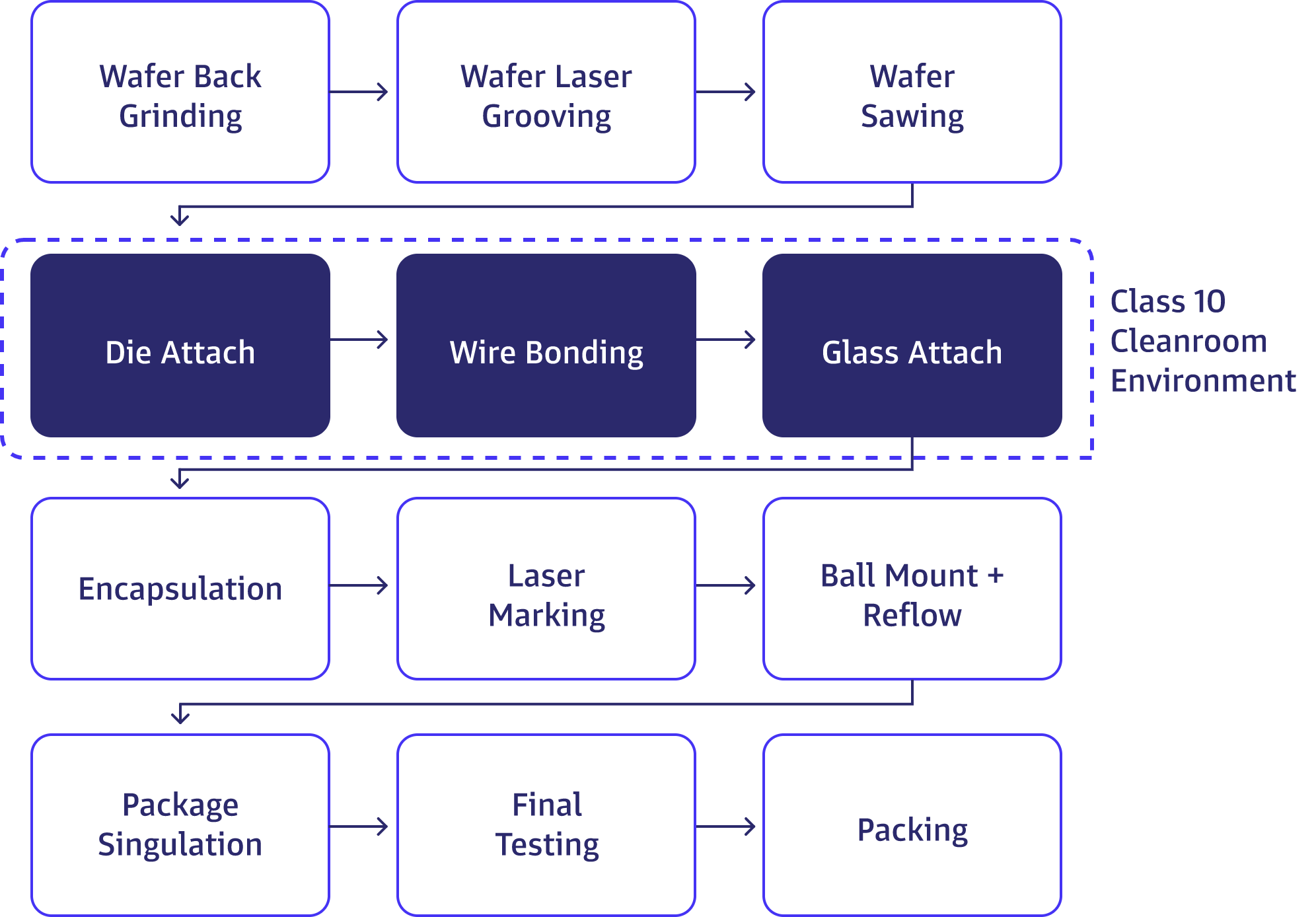

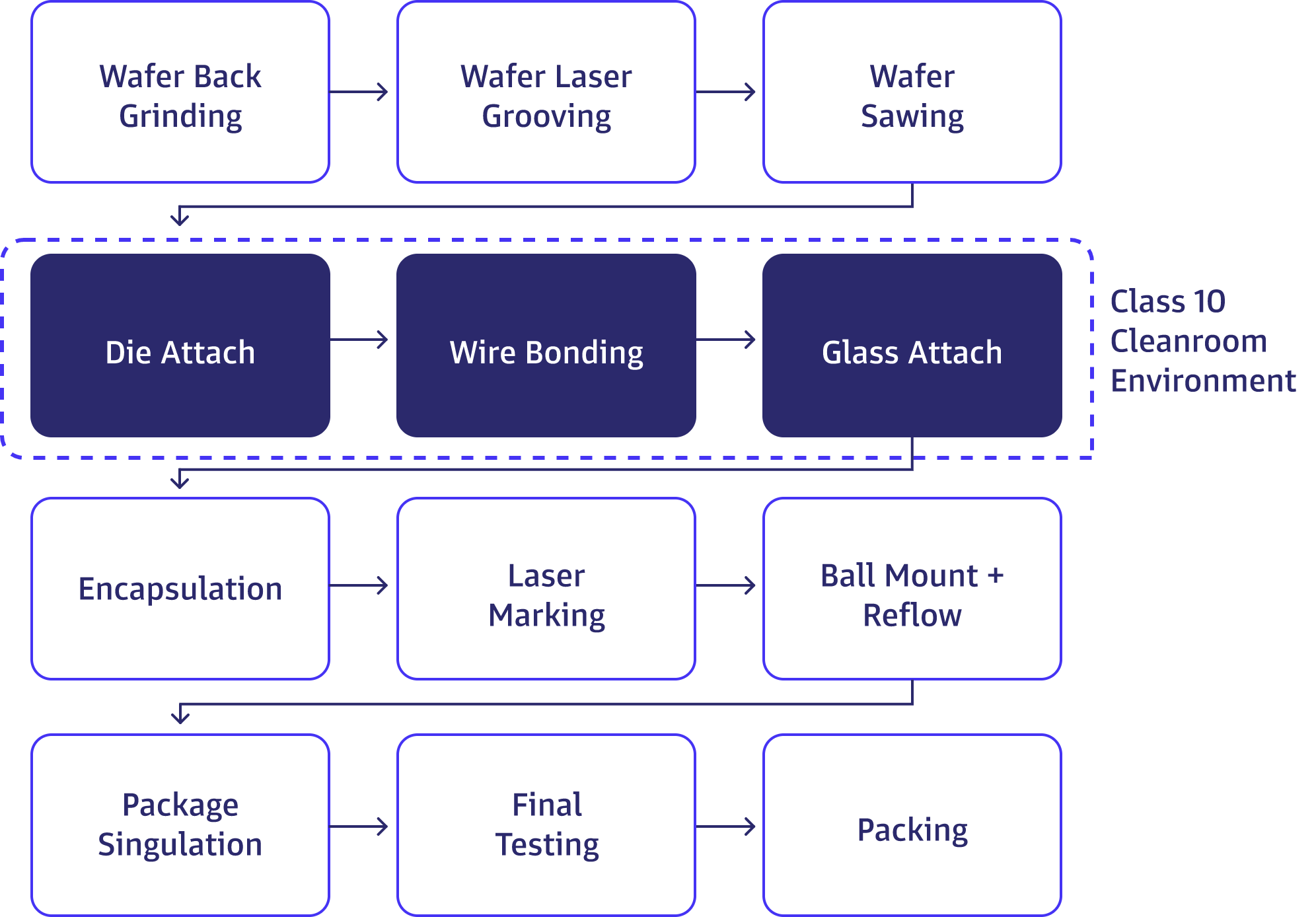

Our production facilities are especially focused on high-end image sensor packaging, boasting a class 10 cleanroom environment for critical assembly processes, fully automated inspection equipment, and specialized cleaning steps – particularly critical for high resolution and small pixel size devices.

The entire packaging and test flow is consolidated under one roof to optimize manufacturing operations. This gives us better control over all production processes, ensuring rapid test execution after assembly and resulting in higher quality, improved yields, and faster cycle times.

High-reliability image sensor packages for ADAS, Autonomous Driving and User Experience applications such as lane detection, obstacle recognition, 360° surround view, gesture recognition, and in-cabin monitoring.

Imaging and Time-of-Flight (ToF) sensors for machine vision, automation, inspection systems and robotics with industrial image sensors.

Surveillance and smart security systems with enhanced resolution and night vision capabilities.

High-end camera modules for smartphones

Through our advanced image sensor packaging development activities, UTAC Group offers a broad range of key enabling technologies to address the needs of next-generation image sensor packages.

With our state-of-the-art test floor, we provide our customers with full turnkey image sensor device manufacturing solutions including wafer probing and final part testing. Our final part testing supports a full automotive flow with tri-temperature capable handlers as well as burn-in capability.

Our testers can support the latest high data rate needs of modern image sensors such as MIPI C-PHY/D-PHY. The handlers are equipped with different illumination sources to cater for different light spectra, with high parallelism capability to reduce test time and overall cost of test.

UTAC Group’s internal test development team supports customers on hardware design, sourcing, test program definition and development – providing a one-stop solution from test plan to production execution.

For full turnkey image sensor device manufacturing solutions or customized production processes, our highly experienced team is equipped to support you with proven, reliable, world-class solutions.